Advanced ADDITIVE manufacturing and 3D printing

We drive advancements in 3D printing and additive manufacturing for complex materials.

THE 3D PRINTING REVOLUTION

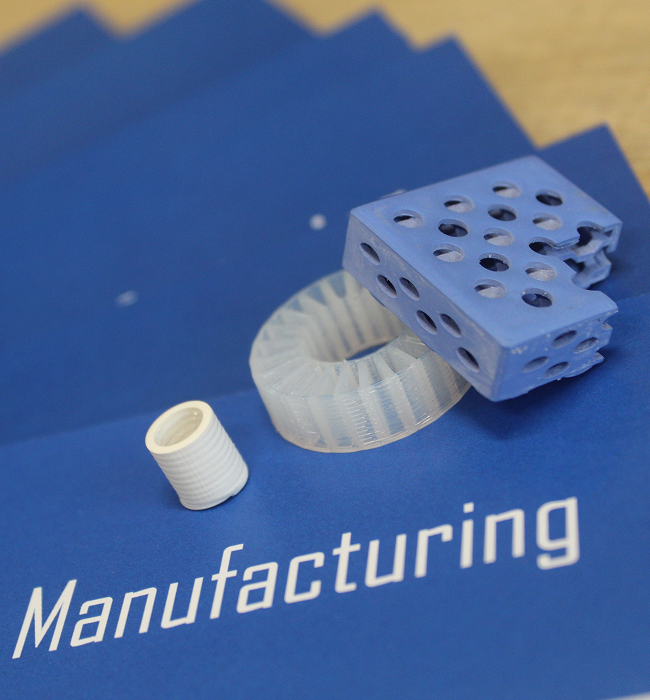

Additive Manufacturing (AM) allows us to create three-dimensional objects layer by layer, offering complex designs with fewer geometric limitations than traditional methods. This technology, which uses everything from polymers to metals, has evolved to allow for custom parts made of materials such as ceramics and composites. Techniques include extrusion deposition, vat photopolymerization, and fused deposition modeling.

At DIOPMA, we implement advanced AM technologies such as Direct Ink Writing (DIW), Stereolithography-based Additive Manufacturing (SLA), and Fused Deposition Modeling (FDM), catering to diverse needs.

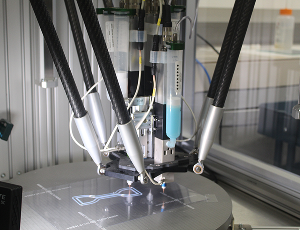

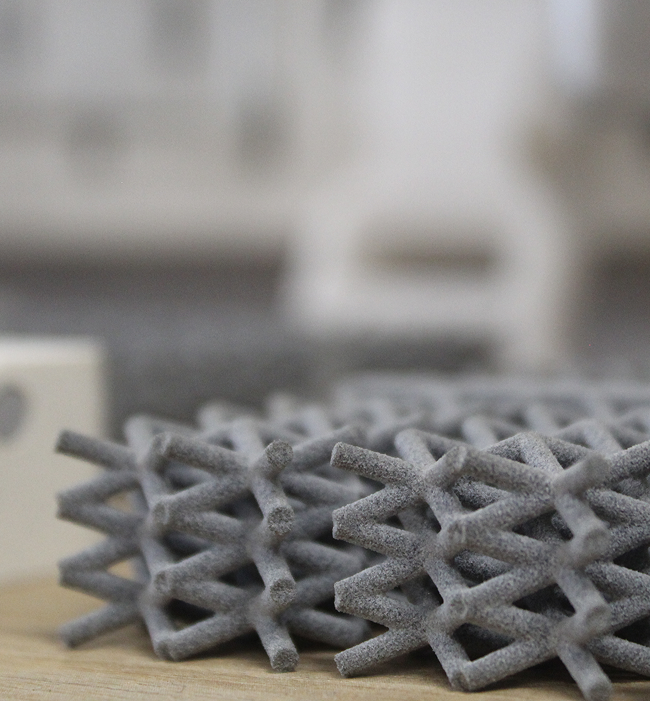

robocasting or direct ink writing

We work on extruding viscous pastes to form 3D objects layer by layer, specializing in solid-loaded pastes for ceramics and metals. Our focus includes research on hydrogels and rheological characterization, enabling the manufacture of highly compatible multi-component parts.

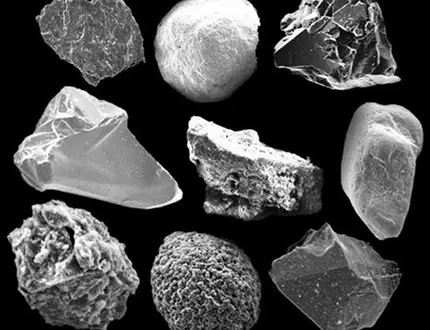

stereolithography-based additive manufacturing

We use this technique to create three-dimensional objects by curing layer by layer photosensitive polymers with radiation. Our research focuses on suspending highly concentrated solids for final ceramic pieces and reinforced composites, requiring post-printing thermal processes for sintering, leveraging our expertise and equipment in formulation and heat treatment.

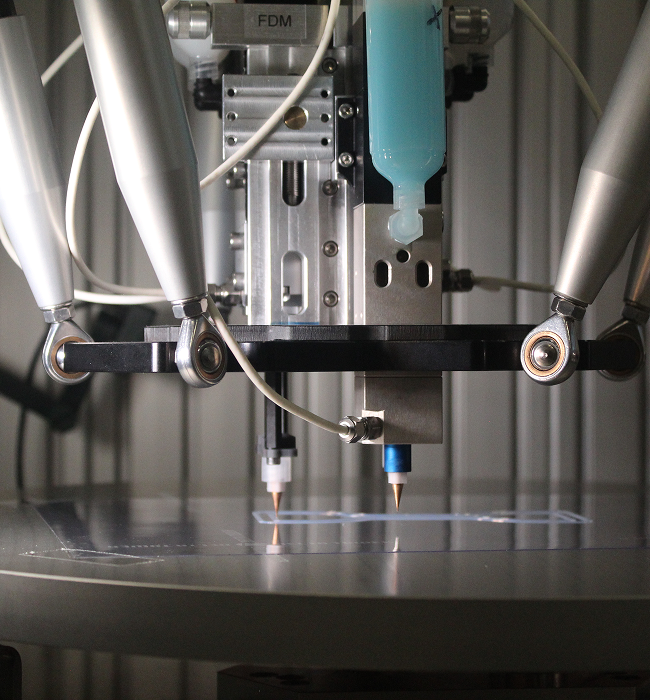

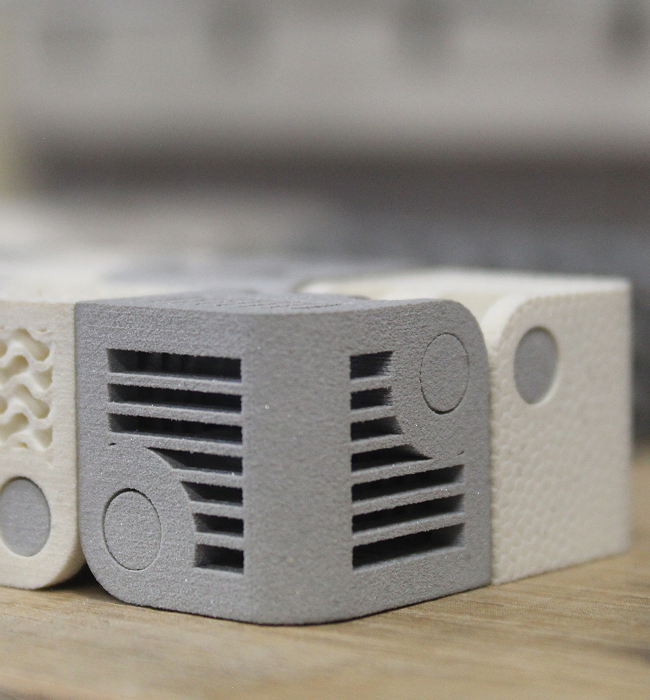

fused deposition modelling

At DIOPMA, we work with Fused Deposition Modeling (FDM) to extrude reinforced polymeric filaments, creating three-dimensional objects layer by layer. Our research focuses on developing and characterizing polymeric composite materials, optimizing their formulation for advanced and specific applications.

LOW-COST ADDITIVE MANUFACTURING

ADDITIVE MANUFACTURING NETWORKS

Our research encompasses the development of specialized materials for CO2 capture and sequestration, as well as research in functional materials, including magnetic ones, which have promising applications. These projects are aligned with sustainability and energy efficiency goals, addressing current environmental challenges.

XaRFA

Network of Additive Manufacturing in Catalonia

MAV Cluster

Materials Avançats de Catalunya

RECENT RESEARCH IN 3D

Latest projects related to additive manufacturing and 3D printing developed by DIOPMA.

3D TEAM

Leading Researchers in Additive Manufacturing and 3D Printing.

Dr. Ma. Elena Xurriguera

Associate Professor

Researcher in Additive Manufacturing, DIW, Robocasting and 3D Printing

Dr. Jose Antonio Padilla

Tenure Track Lecturer

Researcher in Additive Manufacturing, DIW, Robocasting and 3D printing

Dr. Pol Barcelona

Adjunct lecturer

Researcher in Additive Manufacturing, DIW, Robocasting and 3D printing

Joaquim Serra

Pre-Doctoral Researcher

Researcher in 3D printing, Additive Manufacturing, polymers and Life Cycle Assesement

Mariona Roura

Pre-Doctoral Researcher

Researcher in Additive Manufacturing, DIW, Robocasting and 3D printing

CONTACT DIOPMA

Tell us how we can help you and our team will contact you.

© 2025 Centre Diopma. All rights reserved. Legal notice