3D2CE: Desarrollo de materiales con materias primas secundarias y su evaluación funcional para fabricación aditiva de bajo coste hacia una Economía Circular

PID2022-139828OB-C21 – MINISTERIO DE CIENCIA E INNOVACIÓN

The European Commission defined six Key Enabling Technologies in order to provide the basis on innovation and technological

development of the traditional and emerging industries, such as, advanced manufacturing technologies. The use of additive manufacturing

processes has been progressively increased during the last years. Furthermore, additive manufacturing technologies can provide a better

use of raw materials. Consequently, AM processes can be a key factor to achieve a more sustainable manufacturing process into

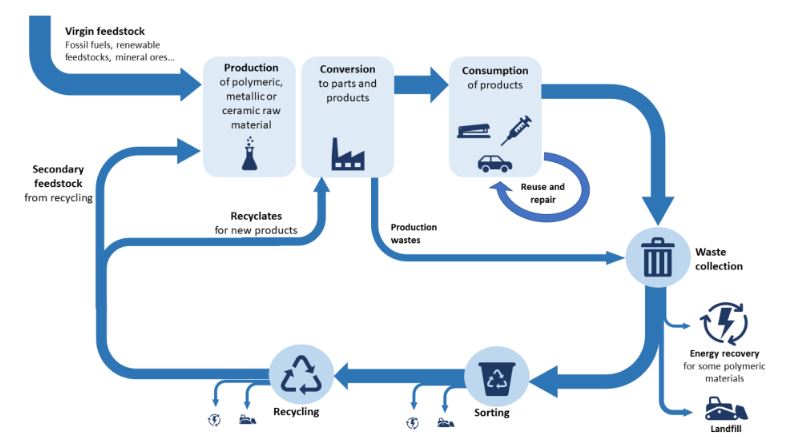

traditional industries reducing the waste of raw materials. Therefore, the reuse, recycling and recovery of material for low cost additive

manufacturing process could be relevant to increase the sustainability of industrial production.

Accordingly, the main objective of the project will be the development and implementation of functional additive manufactured parts

encouraging the reuse and recycling of materials. The research activities will be focused on two different low-cost additive manufacturing

process: Mask Image Projection based on Stereolithography (MIP-SL) and Fused Filament Fabrication (FFF). Materials of different

industrial processes will be reused as reinforcement particles/fibres, to obtain ceramic green parts or leftovers from its own manufacturing

process will be reintroduced as secondary raw materials.

In a first stage, two different approaches will be employed to develop and formulate the material feedstock for AM process. For the MIP-SL

process, recycled or reused material will be used as reinforcement fillers to the base material to enhance the material properties from a

mechanical point of view. For the FFF process, the polymeric leftovers from its own manufacturing process will be reintroduced as a

secondary raw material. Additionally, reused or recycled particles/fibres will also be used as reinforcement fillers. Furthermore, both

technologies (MIP-SL and FFF) will be used to manufacture ceramic green parts using materials with a high solid load content of recycled

ceramic particles. On the other hand, different numerical models will be developed to optimise and analyse the structural behaviour of final

printed parts. A numerical model to simulate the MIP-SL process will be implemented to optimise the printing process in order to enhance

the material photoconversion ratio of reinforced materials. In addition, two different numerical methodologies will be developed to estimate

the main elastic parameters of printed materials. The first one, based on a finite element analysis of a Representative Volume Element

(RVE) and, the second one, based on a machine learning approach.

In the second stage of the project, the functional assessment of printed parts and printing process with recycled and/or reused raw

materials will be analysed by means of experimental test and numerical analyses. Furthermore, a demonstrator, in collaboration with an

industrial company, will be manufactured with different approaches (materials and technologies) presented in this project and their

functionality will be assessed. Finally, an analysis of Life Cycle Assessment (LCA) will be done to assess the environmental sustainability

of the whole process towards a circular economy.

Duration: 2022-2026

PARTNERS

More information: Dr. Elena Xurriguera