Grant PID2021-125810OB-C21 funded by MCIN/AEI/ 10.13039/501100011033 and by “ERDF A way of making Europe”.

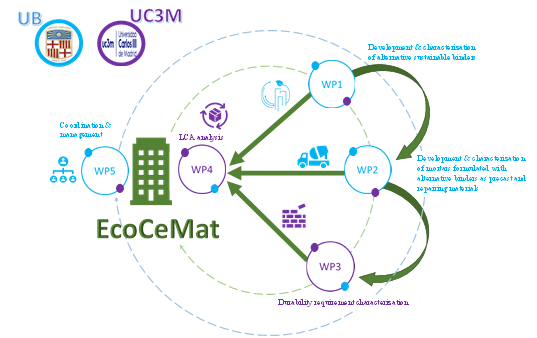

Clays, rich in aluminosilicates, can act as a precursor in alkaline activated cements, being an alternative to Portland cement (PC) and an abundant natural resource. However, thermal activation at high temperatures (500-850 oC) limits the sustainability of the process due to its high energy consumption. The activation of the clay by means of alternative non-thermal processes would suppose an energetic saving. The EcoCeMat project will delve into the mechanical and/or chemical dehydroxylation processes of clays at low temperatures, to increase the amorphous phases and the activity of the aluminosilicates and their availability for the subsequent formation of the cementitious N(C)ASH phases. Once the non-thermal activation of the clays has been achieved, it is intended to increase the sustainable use of the precursor material in: (a) the formulation of alkaline activated cements (AAC) alternative to PC, (b) totally or partially replacing the thermally activated clay used in “limestone calcined clay cements” (LC3), and (c) the use of these alternative cementing materials in the formulation of mortars.

Phosphate-based cements are another promising alternative to PC. Among them, the magnesium and potassium phosphate (MPC) cements stand out, with very competitive properties. The EcoCeMat project proposes the development of MPC using refractory waste generated by the steel industry as a source of magnesium oxide, specifically the one known as tundish tumbling, a basic refractory (rich in MgO) that covers the tundish in the step prior to continuous casting. of steel. In addition, the addition of other residues rich in Si and Al is also considered, which could form magnesium phosphate-potassium silico-aluminates (Si-Al-MPC) and/or magnesium silico-aluminates (MSAH). This opens a new line of research for the formulation of binder materials from secondary resources.

Establishing a synergy between the development of both types of alternative cementing materials, it is intended to study the effect of non-thermally activated clays and tundish in AAC. In this way, innovative hybrid mortars can be formulated as alternatives to PC.

In any case, the development of all these types of mortars of environmental interest implies, for their industrial use, deepening their durability and foreseeable behaviour in service. EcoCeMat proposes a very complete study on the wear behaviour, against freeze-thaw cycles and carbonation phenomena. In addition, it proposes a study of passivation and corrosion of corrugated stainless steel and carbon steel bars embedded in those mortars that would open the door for the use of these new materials in reinforced structures.

After completing the study with life cycle analysis, the use of new cementitious materials with the required technical characteristics and durability, but with a smaller environmental footprint, would be planned for their use in different construction solutions (eg repair materials, preformed and/or architectural concretes).

In conclusion, the multidisciplinary project EcoCeMat aims to develop alternative binders to PC with applications in the field of construction and civil engineering, ensuring the eco-efficiency of cementitious materials and their durability. This will contribute to the sustainability and competitiveness of the construction sector.

Partners:

More information: Josep Maria Chimenos and Joan Formosa Mitjans

Research category: Construction, Environment