Joana Gonçalves Fernandes, Pol Barcelona, Mireia Blanes, Jose Antonio Padilla, Francisco Ramos, Albert Cirera, Elena Xuriguera

https://doi.org/10.1016/j.ceramint.2021.02.167

Ceramics International, Volume 47, Issue 11, Pages 15931 – 15938, 1 June 2021

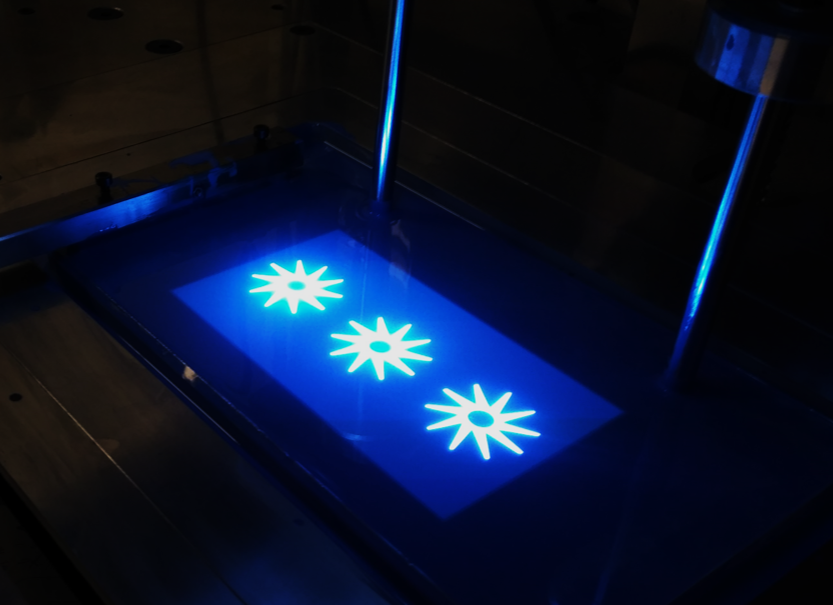

This work presents the development of a photocurable suspension for Digital Light Processing Stereolithography (DLP-SLA) technology using Low-Temperature Co-fired Ceramic (LTCC) materials. LTCC materials are commonly used for high-frequency devices in high-speed data communications, making them an attractive option for electronic applications with direct industrial applicability. The LTCC suspension was prepared with an optimal solid load of 40.4 vol% and characterised by its rheological behaviour, dispersant content, particle size distribution, and photocuring properties in a visible light range. The study also investigated the effect of ball milling on particle size and its impact on viscosity and photocuring behaviour. The optimal mixing range time was determined, emphasising the importance of standardisation in manufacturing photocurable suspensions. The optimized suspension exhibited a viscosity of 3.6 Pa·s at a shear rate of 2 s−1, a sensitivity of 41 μm, and a critical energy dose of 15 mJ cm−2. The production of defect-free printed pieces demonstrated the successful printing process.

Funding

This work was supported by Spanish Government: DPI2016-80119-C3-3-R and RTC-2015-3497-7 (MINECO/FEDER), Catalan Government for Doctorats Industrials (DI-2014), 2017 SGR 118 and BASE 3D (001-P001646).

Research category: Additive Manufacturing

Projects associated: BASE 3D and DPI2016-80119-C3-3-R

Doctoral Thesis: Development and optimization of a Low Temperature Co-fired Ceramic suspension for Mask-Image-Projection-based Stereolithography